Welding bead generation

Dropping in is a time-honored way to re-establish connections with old friends and bond with new ones. The joining of materials by arc welding also uses a "dropping in" process to create a bond. Droplets of filler material from an arc rod fall onto the seam where the materials are being joined. An electric current locally melts the materials causing them to blend and form a strong bond when re-solidified.

A good weld depends on the interplay between a variety of physical processes. Sufficient energy must be applied to have local melting to produce a bond, but not so much as to damage the parts to be welded together. Pools of molten metal grow through convection induced by non-uniform surface tension. An appreciation of this fact is needed to have weld pools that are neither too deep nor too shallow. The filler material should be able to flow and adhere to the base material to produce a smooth weld seam, but not so much that it spreads out over a large surface area.

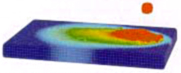

The adjacent figure shows an exploratory computation of droplets of filler material hitting and solidifying on a surface. An energy beam is heating the surface immediately in front of the droplets. The sources for both the drop and the beam are moving steadily across the target surface.

This simulation employs user customizable-routines (for particle generation and beam energy) that can be downloaded from the FLOW-3D support section. Why not drop in and see what else is there that you might find useful?